Widely used in manufacturing industries and construction sites for lifting and lowering heavy loads, Electric Wire Rope Hoists are essential to every industry. They are used to carry out vertical lifting of heavy loads using a drum or lift wheel. Equipped with easy to operate electronic controls and a modern design, electronic wire rope hoists are ideal for 10 tons and above. While many Wire Hoist manufacturers in the market claim to be the best, Hiking Engineers is a name which has earned the title of the best Electric Wire Hoist manufacturers in Ahmedabad owing to its unmatchable range of Hoist cranes that are built for robustness and safety.

Established in 1987, Hiking Engineers has been manufacturing and supplying a wide range of hoist options with very fast lifting speeds. As an ISO and NSIC certified Wire Rope Hoist Manufacturer, we provide the best in class products and are dedicated towards providing the highest levels of client satisfaction. Less susceptible to wear and tear over time, our wire ropes can help you achieve precise vertical placements in no time. With a team of dedicated professionals and engineers, we, at the Hiking Engineers work in the best interests of our clients and provide highly customised and cost effective Electric Wire Rope Hoists.

- A Hoist is a device used for lifting or lowering a load by means of a drum or lift-wheel around which wire rope or chain wraps.

- Cranes and Hoists are somewhat interchangeable terminology since the actual lifting mechanism of a crane is commonly referred to as a Hoist.

- Hoists may be internal to a crane or mounted in affixed position, permanently or temporarily.

- When Hoist is mounted to a trolley on a fixed monorail only two directions of load motion are available: Forward or Reverse & Up or Down. But when the Hoist is mounted on a EOT crane three directions of load motion are available: Right or Left, Forward or Reverse & Up or Down.

- There are two basic hoist lifting media available – one is wire rope hoist which is very durable and will provide long term reliable usage and other type is chain hoist.

- For the given rated load chain hoists are small, compact and light weight compared to wire rope hoists; but for high speed lifting up to (20m/min+) and longer life span with unmatched durability, wire rope hoists are selected over chain hoists because chain over pocket wheel generates fatigue inducing resonance for long lifting cycles.

Wire Rope Hoist Components :-

Wire Rope Hoist Components :-

Frame : - All steel fabricated machined and bolted type. The gearbox is rigidly aligned with the end load plates by substantially holding the transfer members which also from the motor platform for foot mounted motors.

Wire Rope : - 6x37 construction special plough hemp core flexible steel wire rope, having safety factor of 6 for class-II and 7 for class-II duty cycle is provided on the hoist. Galvanized and other construction of rope can be provided for special applications.

Rope Guide : - Standard “Hiking” hoist carries rope guide and pressure ring as standard feature. Cast iron fully encircling guide ring fixed around the sheave grooves of the drum to ensure correct rope lay.

Rope Drum : - The rope drum is made of sturdy seamless pipe or fabricated from steel plated and is grooved to take the full lift without over winding. Large drum dia. to rope dia. ratio reduce wear and cables fatigue. The drum shaft revolves in ball bearing, ensuring smooth running.

Gears : - Alloy steel hobbed teeth helical / spur gears with solid pinions running on ball / roller bearing with oil splashed type lubrication.

Bottom Block :- Bottom block assembly consisting of drop forged steel hook mounted on thrust bearing with large diameter sheave and hook plates made out of steel.

Motor : - Foot mounted squirrel cage induction motor designed and manufactured to Is-325 of reputed make is used. Motors are totally enclosed half hour rated with high starting torque, specially designed and built for hoist duty. The motors as well as brakes are provided with class-F insulation.

Brake : - Disc type spring loaded brakes are provided for heavy duty operation. Brakes are mounted on the non-driving end of the motor and are easily accessible for manual release.

Limit Switch : - To avoid over winding of wire rope, limit switches are provided with each hoist, which ensures the highest and lowest position of load hook.

Controls : - Every hoist is provided with a control panel comprising of Siemens/L&T/Schneider make heavy duty, directed-on line reversing type airbrake connector, transformers and fuses. All these are housed in dust proof MS fabricated sheet metal cabinet. The pendant push button station is duly suspended by steel chain or wire rope at 230/110 volts to avoid accident.

WIRE ROPE HOIST WITH 90° RADIUS of ROTATION

Advantages of Wire Rope Hoist :-

Advantages of Wire Rope Hoist :-

- Very fast lifting speeds than a chain hoist.

- Silent in operation than a chain hoist.

- No room taken up by chain or chain receptacle.

- Recommended for considerable long lifting height.

- Very smooth lifting operation such as handling of Glass panels.

- Heavy safe working load up to 25 Tons.

Flameproof Wire Rope Hoist :

Flameproof Wire Rope Hoist :

Hiking wire rope hoist are specially built with flameproof electrical to suit hazardous areas in chemical plants, confirming to IS: 2148, all electrical components are duly certified by CMRS (central mining research station), Dhanbad, for classified gas groups I, IIA, IIB.

Different Types Of Lifter Used With Wire Rope Hoist :

Different Types Of Lifter Used With Wire Rope Hoist :

FIXED MOUNTING POINT LIFTER

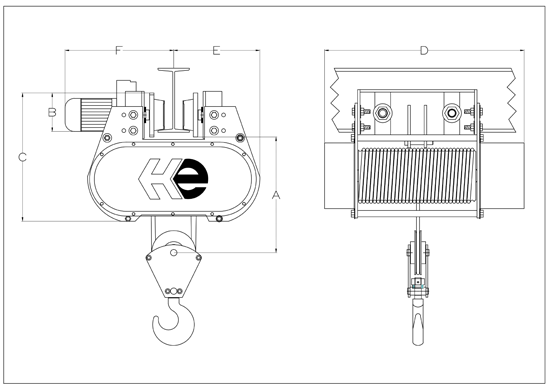

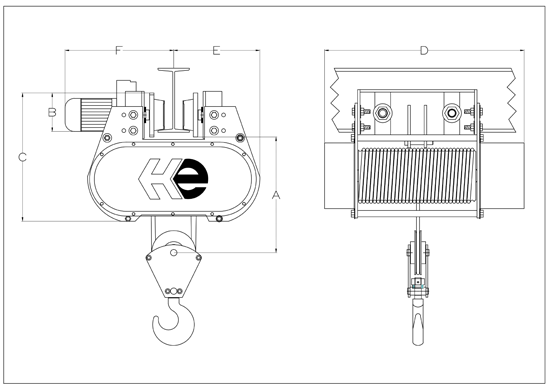

Technical Specification :-

Technical Specification :-

SWL

KGs. |

Height

of lift

(Meter) |

No.

of

falls |

Hoisting

speed

(m/min) |

Cross

Travel

(m/min) |

Motor

HP for

Hoist |

Motor

HP for

C.T |

Flange

width

of ISMB |

Wire

Rope

Dia.(mm) |

A |

B |

C |

D |

E |

F |

Approx

Weight

KGs. |

| 1000 |

6 |

2 |

5.0 |

18 |

1 |

0.25 |

100-125 |

8 |

425 |

175 |

425 |

650 |

290 |

400 |

150 |

| 2000 |

6 |

2 |

4.0 |

18 |

1.5 |

0.25 |

125-140 |

10 |

450 |

175 |

425 |

650 |

290 |

400 |

170 |

| 3000 |

6 |

2 |

4.0 |

16 |

3.0 |

0.50 |

125-140 |

10 |

600 |

200 |

650 |

900 |

310 |

520 |

400 |

| 5000 |

6 |

4 |

3.5 |

16 |

5.0 |

1.00 |

150-210 |

12 |

750 |

200 |

740 |

1050 |

350 |

550 |

450 |

| 7500 |

6 |

4 |

3.5 |

16 |

7.5 |

1.00 |

150-210 |

12 |

850 |

200 |

740 |

1200 |

400 |

550 |

550 |

| 10000 |

6 |

4 |

3.0 |

15 |

10.0 |

1.25 |

210-225 |

16 |

950 |

250 |

930 |

1700 |

620 |

720 |

1000 |

| 15000 |

6 |

4 |

2.5 |

12 |

12.5 |

1.50 |

225-250 |

16 |

1000 |

250 |

930 |

1700 |

620 |

720 |

1200 |

| 20000 |

6 |

4 |

2.0 |

12 |

18.0 |

2.00 |

250-300 |

16 |

1400 |

300 |

1100 |

1850 |

750 |

900 |

1600 |

| 25000 |

6 |

4 |

2.0 |

12 |

20.0 |

2.00 |

300-330 |

16 |

1600 |

325 |

1150 |

1850 |

750 |

900 |

2200 |

Wire Rope Hoist Components :-

Wire Rope Hoist Components :- Advantages of Wire Rope Hoist :-

Advantages of Wire Rope Hoist :- Flameproof Wire Rope Hoist :

Flameproof Wire Rope Hoist : Different Types Of Lifter Used With Wire Rope Hoist :

Different Types Of Lifter Used With Wire Rope Hoist : Technical Specification :-

Technical Specification :-